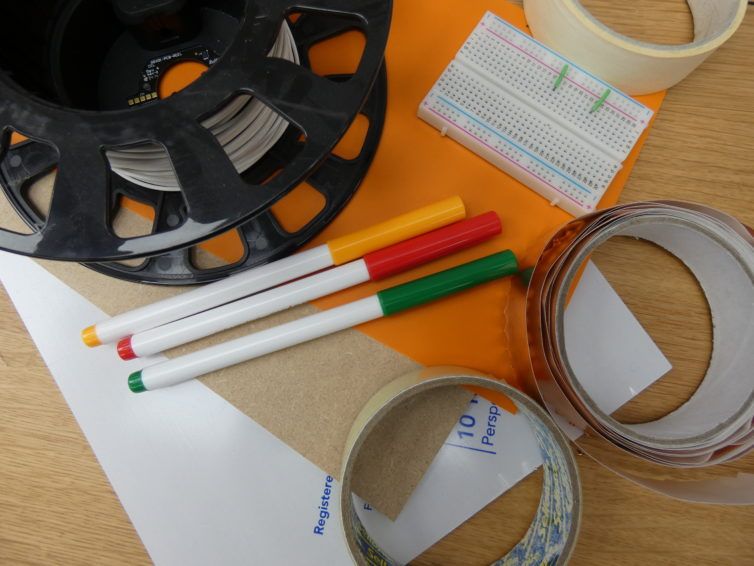

Home / IT & Computer Science / AI & Robotics / Build a Physical Computing Prototype / Prototyping Materials

Reach your personal and professional goals

Unlock access to hundreds of expert online courses and degrees from top universities and educators to gain accredited qualifications and professional CV-building certificates.

Join over 18 million learners to launch, switch or build upon your career, all at your own pace, across a wide range of topic areas.