Home / Healthcare & Medicine / Biology & Biotechnology / Discover Dentistry / “Making Faces” with Professor Ric van Noort

Reach your personal and professional goals

Unlock access to hundreds of expert online courses and degrees from top universities and educators to gain accredited qualifications and professional CV-building certificates.

Join over 18 million learners to launch, switch or build upon your career, all at your own pace, across a wide range of topic areas.

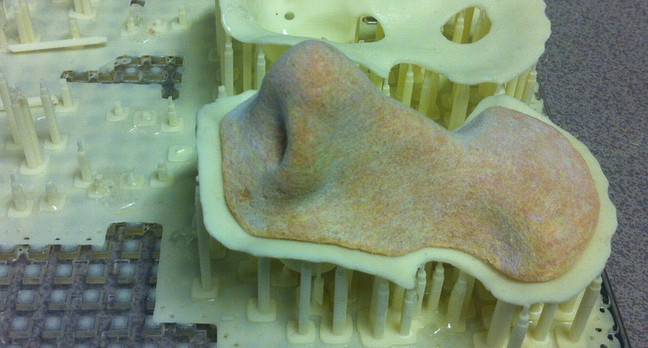

A 3D printed skull produced from a CT scan (computerised tomography scan, also known as a CAT scan) used to construct facial prosthesis.

A 3D printed skull produced from a CT scan (computerised tomography scan, also known as a CAT scan) used to construct facial prosthesis. Experimental 3D printed nose produced using powder and binder printing combined with up to four inkjet heads to reproduce colour. Currently produced from a scan of the original prostheses, but computer design methods are being researched.

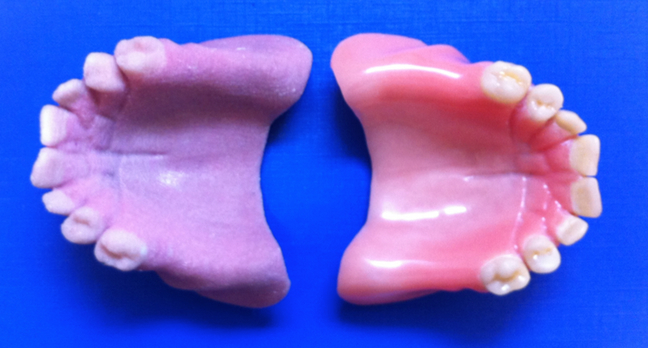

Experimental 3D printed nose produced using powder and binder printing combined with up to four inkjet heads to reproduce colour. Currently produced from a scan of the original prostheses, but computer design methods are being researched. Experimental 3D printed denture (left) produced using powder and binder printing. This one was produced from a scan of the original made using the conventional laboratory technique, but methods to produce the complete denture digitally (from a digital scan of the mouth to the printed denture) are currently being researched.

Experimental 3D printed denture (left) produced using powder and binder printing. This one was produced from a scan of the original made using the conventional laboratory technique, but methods to produce the complete denture digitally (from a digital scan of the mouth to the printed denture) are currently being researched.