Mitigation and early warning of health challenges at aquaculture sites

Diseases can cause serious problems on fish farms. They may reduce growth and yields, influence the market price of the product, or in severe cases lead to large-scale mortality with significant animal health and economic consequences.

As we have seen in step 2.10, fish diseases can be caused by a range of, primarily natural, factors.

Mitigation of disease

The primary measure to mitigate fish disease is good husbandry. This includes regular cleaning and disinfection of equipment, as well as workers’ clothing, boots and other gear before contact with healthy fish. However, diseases do occur even without human contact, and to ensure compliance and consistency, if a notifiable disease is confirmed in the UK, the Fish Health Inspectorate places controls in place to limit the spread of disease (these are known as confirmed designations).

Some fish diseases, such as Infectious salmon anaemia (ISA) cannot be treated and hence is simply controlled by restricting movement of fish from one location to another.

Following the Covid-19 pandemic, we are all now familiar with the potential for vaccines to mitigate viral disease, with vaccination being increasingly used to treat a range of viral-induced diseases in farmed fish.

Similar to land-based agriculture, bacterial infections can potentially be treated through the use of antibiotics. As we have seen in step 2.13, the increase in antibiotic resistance is a global health concern, so considerable effort is being put into the reduction of antibiotics through processes such as vaccination. Considerable strides are being made in this regard with the major Scottish salmon farming company Scottish Sea Farms achieving zero antibiotic use in 2020.[1]

However, as with all actions there can sometimes be unintended consequences, and some studies have shown vaccinations can make fish more susceptible to co-infection by other factors.[4]

There are also limitations, as some bacterial diseases have no licensed vaccines or antibiotic treatments. An example of this is Bacterial Kidney Disease (BKD). For BKD, the most effective method of control is therefore the prevention of movements of live fish. Eggs from infected farms are not permitted to be used as broodstock. Management strategies designed to control BKD include good hygiene, quarantine of infected stocks, culling of infected broodstock and if the outbreak is in a hatchery, total depopulation followed by disinfection.

Other diseases such as amoebic gill disease can be treated by freshwater bathing for 2-3 hours which kills the causative amoebae that cannot handle low salinity water.[8]

*Husbandry: the care, cultivation, and breeding of crops or animals.

*Broodstock: mature fish used for breeding purposes.

Sea lice

Sea lice (parasitic copepod crustaceans) are perhaps the greatest concern to salmon farmers and fortunately, there are a number of approaches to control their numbers. The first is related to the positioning of fish farms. Sea lice drift naturally on oceanic currents, so fish farms can act as staging posts where lice can breed and multiply before setting off on the next stage of their journey.

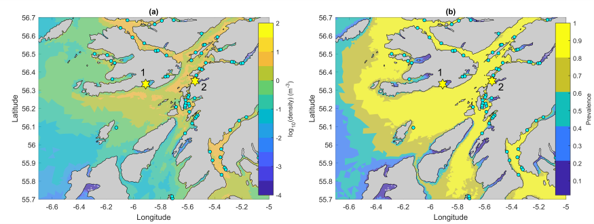

With an understanding of the biology of the lice and the oceanography of a region, it is possible to use mathematical modelling approaches to determine where best to locate farms to break the chain of transmission from one farm to another. Figure 1 shows modelled sea lice density and prevalence (proportion of weeks when lice were present) on the Scottish West coast should new fish farm sites be introduced. Hypothetical new sites are marked by yellow stars and existing sites by black dots.

Click to expand Figure 1: Sea lice modelling

Click to expand Figure 1: Sea lice modelling

Should lice become established at a particular farm, a number of control measures are possible. Chemical treatments can decrease sea lice infestations, but some can have a detrimental impact on the environment nearby. Hence, hydrogen peroxide H2O2 is often used as it has reported low environmental toxicity.[9] Its mechanism of action against sea lice is not well understood, but it has been observed to cause sea lice to detach from the host.

Unfortunately, this detachment may only be temporary, and a large proportion of lice may recover post-exposure with researchers showing that 89% recovered within 36 hours after H2O2 exposure.[5] Researchers have also noted the ability of treated lice to re-infect hosts.[10]

Sea lice resistance to treatments is an issue for the fish farming industry. While initially, the industry met this resistance with increased dosages, such an approach is potentially damaging not only the environment but also the fish, as they do not develop resistance at the same pace as the parasites.[6] Other control measures, including mechanical and biological approaches, have therefore become common.

Physical treatments include mechanical approaches, such as the “Hydrolicer” and “Thermolicer”. A Hydrolicer uses low-pressure jets of seawater at ambient temperature to remove lice. A Thermolicer is a similar water-based removal treatment that uses water at 30-34oC to remove lice, as sea lice have a low tolerance for changes in temperature. The salmon get passed through the processing loop in 25-30 seconds before being returned to their pens.

There are no significant environmental impacts from using a Thermolicer. However, as fish are physically pumped through the system, it can be somewhat abrasive for the fish and hence cannot be overused.

Adding cleaner fish to sea-cages is a biological approach to the removal of sea lice as they feed on sea lice. Species such as lumpfish (Cyclopterus lumpus) and wrasse (Labrus bergylta) have also been confirmed to feed on sea lice and offer a greener option to the other treatments. However, their beneficial effects remain to be fully understood as farms that use these or other cleaner fish species still also rely on chemical and mechanical anti-parasite treatments and continue to report high sea lice prevalence.[7] Cleaner fish may also as vectors for several Atlantic salmon pathogens and their translocation.[6]

New optical technologies are being developed to allow automated counting and treatment of sea lice within a farm. This reduces the need for handling (and stressing) the fish and will hopefully allow treatment to be applied earlier, hence improving fish health.

Overall, when accounting for the total cost of sea lice control treatments, decreased fish growth, administering more feed, and sea lice-related mortality, it is expected that up to 10% of the industry’s revenue is lost.[2,3]

Impacts of harmful algal bloom (HAB)

The primary mitigation measures at a fish farm that is impacted by a HAB is to cease feeding. This reduces the oxygen demand of the fish which is higher when feeding, and may also allow them to swim more freely and deeper in the pen, potentially avoiding a bloom should it be located at the surface.

Other mitigation measures might include harvesting fish early if their stage of development allows, moving fish to another site, or deploying physical “skirts” or bubble curtains around farms (although the effectiveness of these measures remains in debate). In Asia some success has been achieved through the addition of modified clay to the water column that removes the algal cells as it sinks.

In all of these cases, it is important that there is sufficient early warning of the bloom to allow action to be taken. Most fish farms conduct daily microscope-based monitoring of phytoplankton at the farm. Typically, these counts are undertaken following the collection of a water sample in a plankton net and are undertaken immediately on a live sample.

|

Figure 2: Plankton net |

For shellfish toxin-producing, HABs, the main method of early warning is also through microscope-based water testing to identify any HAB taxa present, but given their potential impact on human health, this is conducted under the control of a competent authority (in Scotland this is Food Standards Scotland). The method of operation differs slightly between countries but follows a similar pattern. In Scotland, water samples are collected on a weekly basis from 40 representative locations. Based on the data gained from these tests, the regulator can decide to close a shellfishery should there be a risk of human toxicity from the shellfish.

In the below video, you’ll discover how water samples are being monitored:

This is an additional video, hosted on YouTube.

Such regulatory monitoring systems are very successful, and incidences of shellfish toxicity in humans are rare. The last recorded case of human toxicity from farmed Scottish shellfish was in 2013.[11] Fortunately, toxins eventually clear from the shellfish, and the produce then becomes safe for sale and consumption. However, unexpected site closures, or worse, product recalls, can be very expensive for shellfish companies.

Early warning is therefore key for aquaculture companies to plan their operations. As HABs are spatially and temporally variable this typically comes in the form of a risk assessment similar to a weather forecast that combines available biological and physical information with expert interpretation, to forecast risk for the following week. In Scottish waters, this is provided via www.HABreports.org

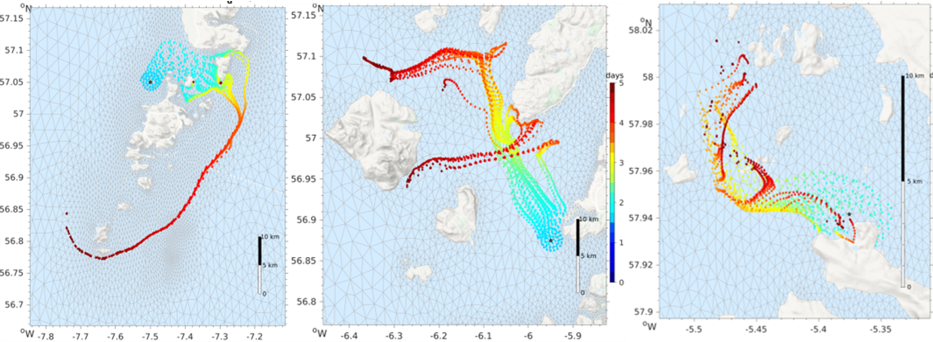

Mathematical modelling approaches offer the potential to predict the transport and development of HABs. Most applications utilise models that simulate the movement of particles representing algal cells, see below. Such models can predict the development of a bloom up to ~ 1 week in advance of its appearance at a particular location. Important to this approach is good information to initiate the model either from remote sensing by satellite (for high biomass blooms) or from microscope-based counts.

Click to expand Figure 3: Model output

Click to expand Figure 3: Model output

Conceptually, monitoring and early warning of jellyfish could be undertaken in a similar manner, but these organisms are more difficult to monitor, particularly by remote sensing.

Author: Professor Keith Davidson

Share this

Sustainable Seafood: Barriers and Opportunities in the Fishing Industry

Sustainable Seafood: Barriers and Opportunities in the Fishing Industry

Reach your personal and professional goals

Unlock access to hundreds of expert online courses and degrees from top universities and educators to gain accredited qualifications and professional CV-building certificates.

Join over 18 million learners to launch, switch or build upon your career, all at your own pace, across a wide range of topic areas.

Register to receive updates

-

Create an account to receive our newsletter, course recommendations and promotions.

Register for free