Control measures

Share this step

Hierarchy of control measures

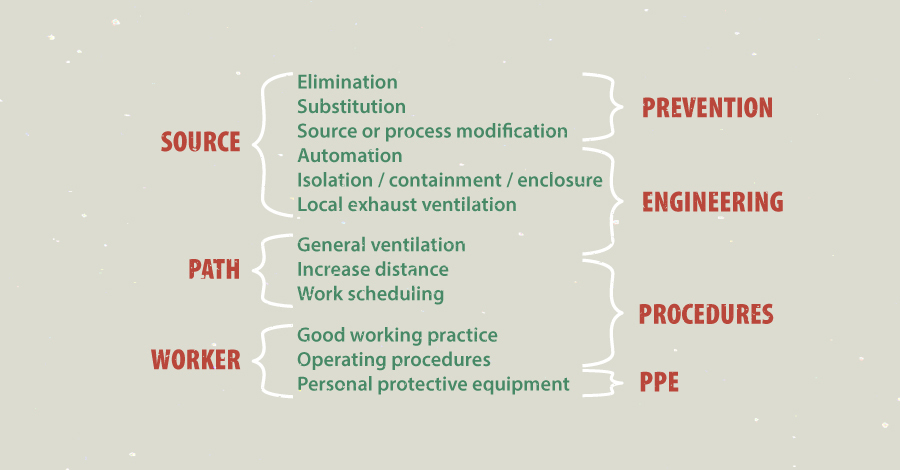

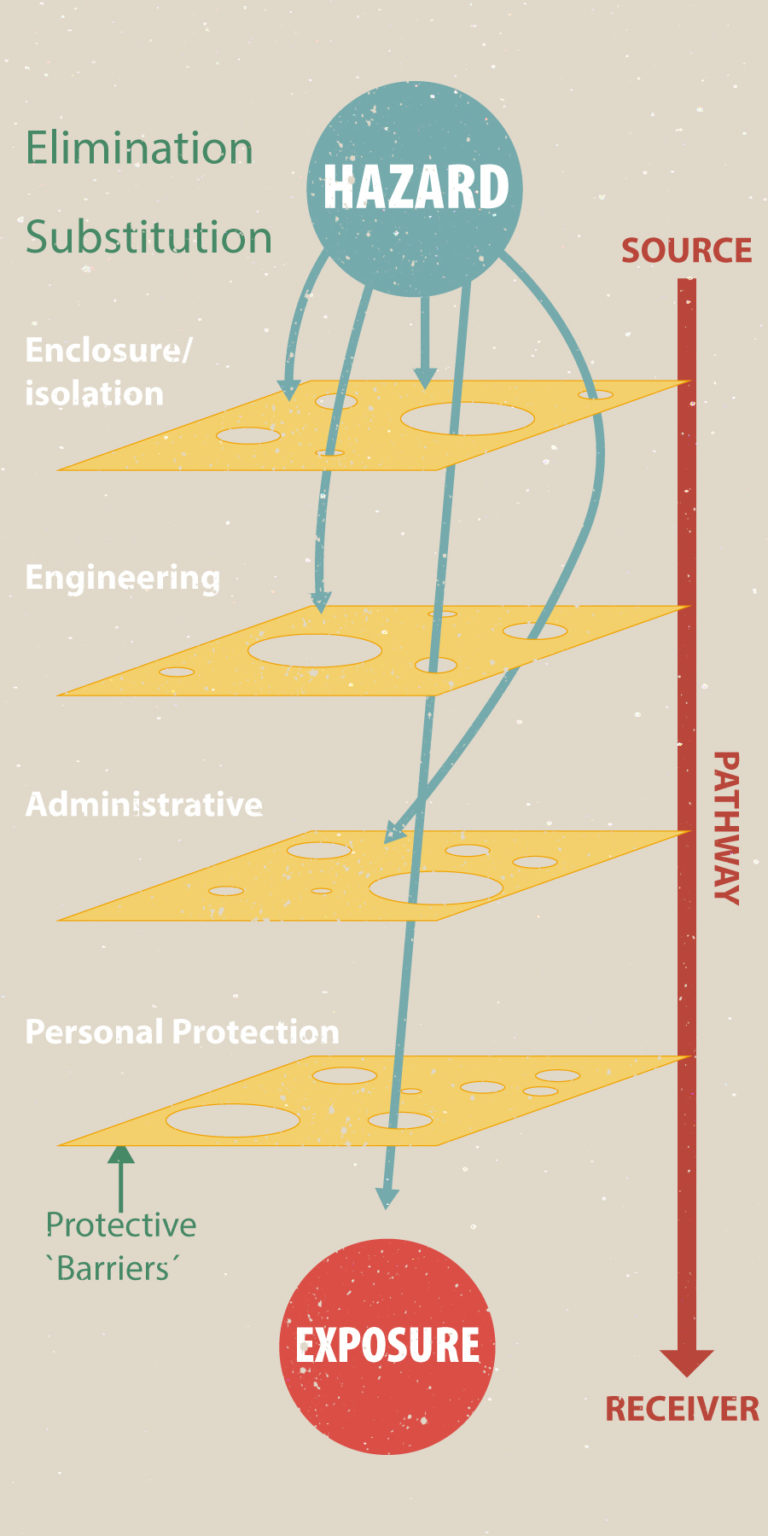

As illustrated in the previous example there are many ways of reducing the risk of negative health effects at the workplace. The control measures to reduce risks can be categorized in terms of administrative and engineering controls, and/or in terms of control location, i.e. source, path and receiver (Figure below).

Control measures to reduce exposures could be established at the source, the path and/or at the receiver/worker. ©University of Bergen

Control measures to reduce exposures could be established at the source, the path and/or at the receiver/worker. ©University of Bergen

Examples of different ways to group a set of control measures. ©University of Bergen

Examples of different ways to group a set of control measures. ©University of Bergen

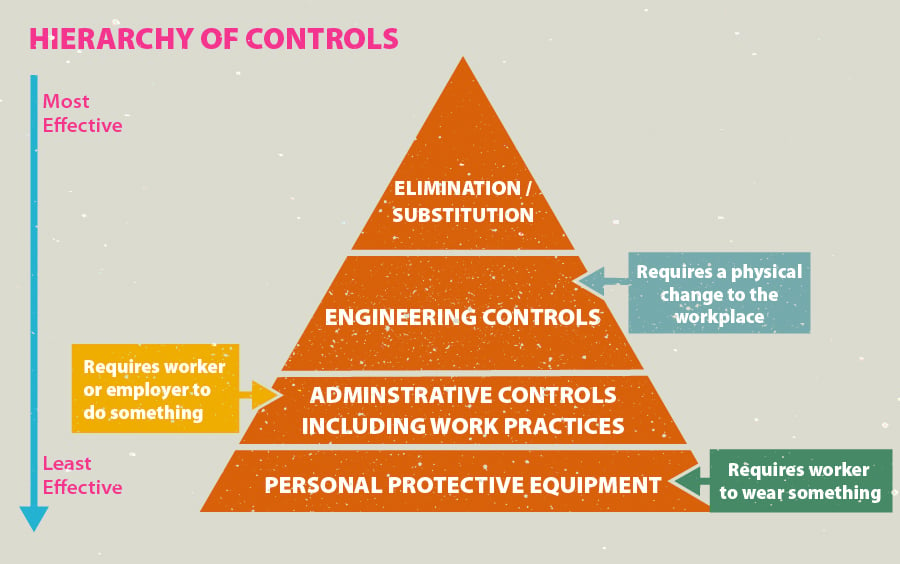

The best way to achieve control is by addressing the source of the hazard/contamination, and consequently this is placed on top of the control measure hierarchy. Substitution of currently-used materials with less hazardous materials is one of the most effective ways for eliminating or reducing exposure to materials that are toxic or pose other hazards.

If control by source cannot be achieved or does not resolve the problem then an attempt should be made to control the risk by interrupting the path of exposure between the hazardous material and the worker/receiver. In terms of “path”, engineering controls are preferrable to administrative/procedural controls: This is not necessarily due to a question of effectiveness but more to the potential longevity of the measure. While an engineering control requires a physical change to the workplace, administrative controls require the workers or employers to do something.

Personal protective equipment is considered to be the least effective measure and is placed at the bottom of the control hierarchy. Personal Protective Equipment (PPE) requires the workers to wear something and should be the last resort for reducing exposures. It is only if none of the measures in the upper part of the control hierarchy can be achieved, should one resort to a situation where the primary control measures are based around the workers themselves.

The hierarchy of control measures, with the most effective measures at the top of the pyramide. ©University of Bergen

The hierarchy of control measures, with the most effective measures at the top of the pyramide. ©University of Bergen

In summary, when deciding on what controls can be used, start at the top and work down the list considering each measure in turn, and try to use measures that are higher up in the hierarchy. This means that although PPE can often be used, it should not be the first choice when controlling exposure to a hazard.

Measures that can be applied at the source of the contamination include:

- Eliminate the source, – examples;

o use electric instead of diesel powered forklift trucks

o use automatic instead of manual machines for hazardous work such as cutting and skinning - Substitution – using a less hazardous chemical or process;

o asbestos has been banned in many countries, and is substituted by synthetic mineral fibers for insulation

o lead in paint has been substituted by e.g. zink and titanium dioxides - Isolation / containment / enclosure;

o enclose sources or the employee, or the source and some employees together rather than all employees

o place the source in a separate location from the employees - Modification of the source or process

o replace dry sweeping with broom with vacuum cleaning or wet methods

o use pellets instead of powders

o use pre-mixed or diluted chemicals instead of manually mixing or diluting chemicals at the workplace - Automation – use robotics, remote or computer aided products

- Local exhaust ventilation – using ventilation to capture the contaminant at the source, to prevent it dispersing

A demonstration of the high exposures you can get sweeping up and blowing down compared to using a vacuum cleaner with HEPA filters is illustrated by this HSE, UK video.

Control along the path

When the contaminant is dispersing, it is more difficult and fewer options are available. They include;

- General ventilation – which dilutes the contaminant concentration

- Increasing the distance between the source and the workers (i.e.: increasing the length of the pathway so that there is more dispersion and dilution)

- Use of screens and partial barriers

Worker based (receiver) controls include:

- Administrative controls – rotating workers, limiting the length of time they work in a location

- Personal protective equipment (PPE) – wearing something that decreases or limits the effects of the contaminant (Note: the contaminant has already reached the worker).

Personal protective equipment

Different types of personal protective equipment (PPE) are illustrated below.

Head protection. ©Colourbox

Head protection. ©Colourbox

Eye & Face protection. ©Colourbox

Eye & Face protection. ©Colourbox

Hearing protection. ©Colourbox

Hearing protection. ©Colourbox

Respiratory protection. ©Colourbox

Respiratory protection. ©Colourbox

Hands / Gloves protection. ©Colourbox

Hands / Gloves protection. ©Colourbox

Body / Clothing protection. ©Colourbox

Body / Clothing protection. ©Colourbox

Foot protection. ©Colourbox

Foot protection. ©Colourbox

Protection against falling. ©Colourbox

Protection against falling. ©Colourbox

Personal protective equipment – chemical exposure

The personal protective equipment required depends on the type of chemical compound used in any given process, and the protection necessary to reduce exposure to acceptable levels. For instance, when selecting gloves one has to take into account that different glove materials provide different levels of resistance to the effects of hazardous chemicals. This is related to the ability of the chemical to penetrate, degrade and/or penetrate through the glove material. A range of different glove materials exists, such as latex, nitrile, PVC and neoprene. Glove charts are available from the manufacturers to assist in selecting type of gloves to use when working with chemicals. However, expert knowledge is needed to make the appropriate choice for particular task and chemicals.

Similarly, there is a broad range of different types of personal respiratory protective devices (respirators). There are two main types of Air Purifying Respirators. These are effective against either:

- contaminants in particulate form or

- contaminants in gaseous or vapour form

There are also combination filters (particulate and gas or vapour) for use where both hazards are present.

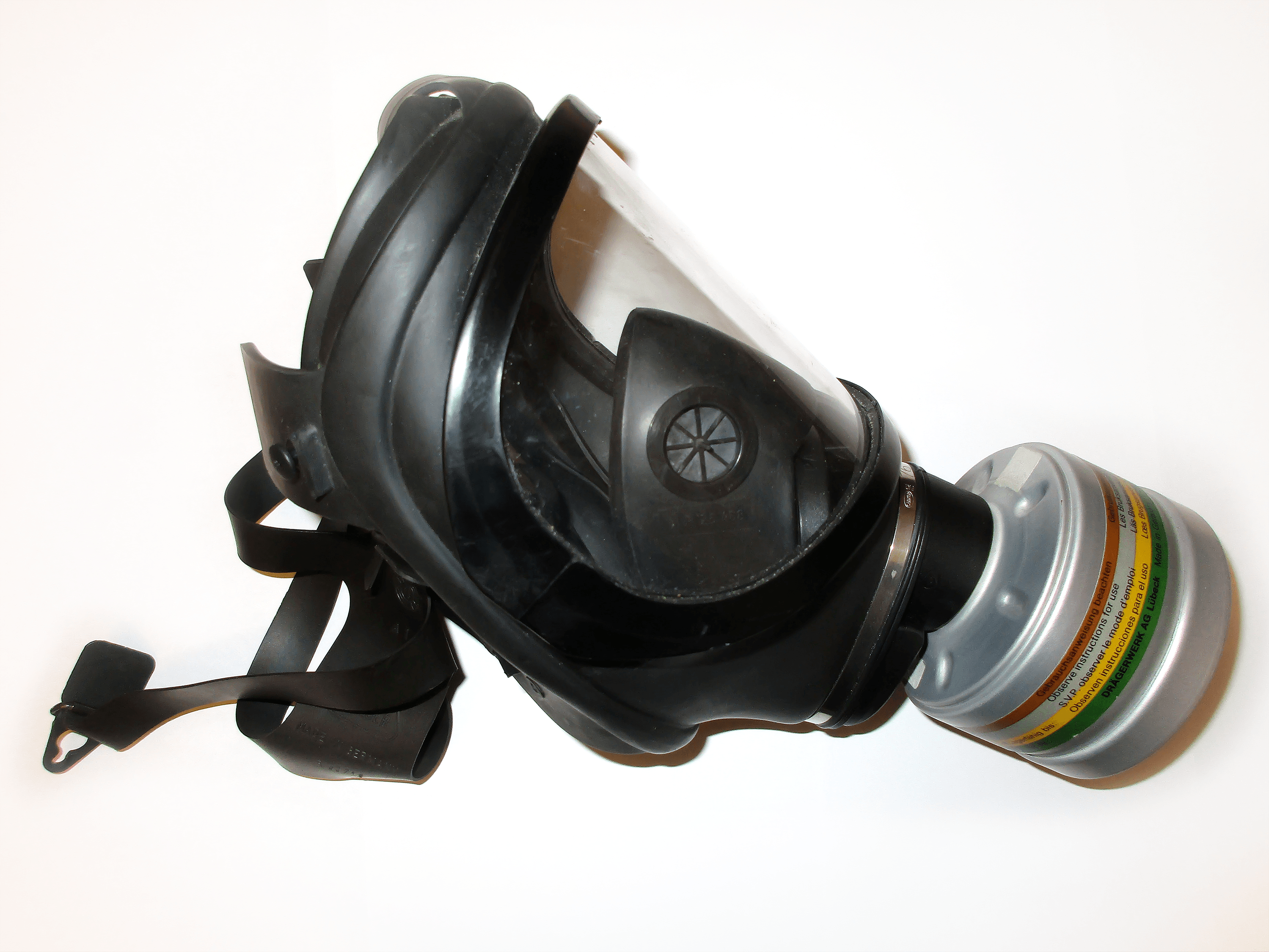

The recommended type of air purifying respirator to use also depends on the levels of protection needed for the particular contaminant. The protection level increases from disposable half-masks to reusable half-masks and full-face masks.

Disposable halfmask. © G. Tjalvin

Reusable half mask. © G. Tjalvin

Full-face mask. © G. Tjalvin

Full-face mask. © G. Tjalvin

Powered masks; Contaminated air is drawn through the filter by a fan. As illustrated in the photo the filter and the fan are attached to the belt and worn at the back. Filtered air is then delivered to the space enclosed by the head covering. These devices are often called Powered Air Purifying. © G. Tjalvin

Powered masks; Contaminated air is drawn through the filter by a fan. As illustrated in the photo the filter and the fan are attached to the belt and worn at the back. Filtered air is then delivered to the space enclosed by the head covering. These devices are often called Powered Air Purifying. © G. Tjalvin

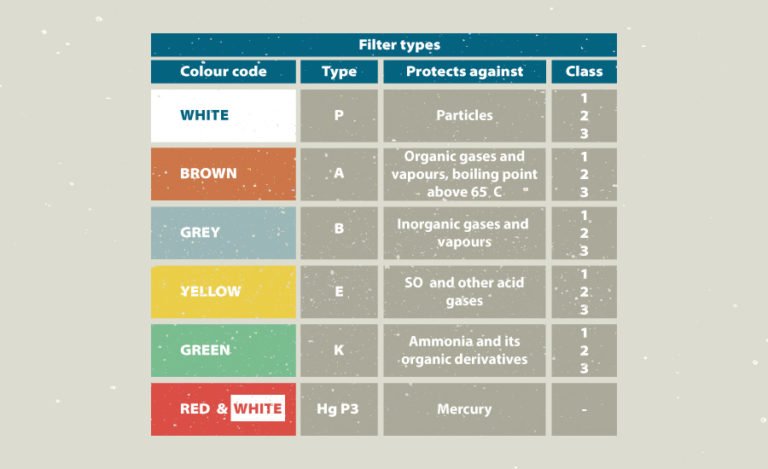

Filter cartridges for particles, gases and vapours have colour codes to indicate which contaminant they protect against. For instance the brown filter cartridges are effective against vapour from organic solvents in paint products. There are class 1, 2 and 3 which codes for increasing absorption capacity.

Particle filters have a white colour code while the three classes, P1, P2 & P3, indicate increasing filtering efficiency.

An example of a combination filter is the Red & White cartridge, which protects from mercury and particles.

Filter cartridges for gases and vapours have colour codes to indicate which contaminant they protect against.© University of Bergen/Arjun Ahluwalia

Filter cartridges for gases and vapours have colour codes to indicate which contaminant they protect against.© University of Bergen/Arjun Ahluwalia

The composition of combination filters can be tailored according to the gases, vapour and particles they should protect against.

An example of a reusable half mask with combination filter, as indicated by the colour codes on the filter cartridge.©Colourbox

An example of a reusable half mask with combination filter, as indicated by the colour codes on the filter cartridge.©Colourbox

For situations involving insufficient oxygen, an Air Supplied Respirator is needed to deliver breathing-quality air to the wearer from an independent source (airline or self-contained breathing apparatus). A supplied-air respirator is the preferred respirator for use when spray painting with isocyanate-containing paint. Supplied air respirators are generally considered to offer more protection than air-purifying respirators with filters, as long as the former are well-maintained and worn properly. The head or face pieces for supplied-air respirators come in several types, including half- or full-face masks, hoods, and loose fitting face pieces.

Using a Combination of Controls or “The Swiss Cheese Model”

In many cases, it will be necessary to use a combination of measures to appropriately manage risk exposure. For example, a toxic chemical could be replaced with a less hazardous one (substitution), safe work procedures (administrative measures) can be introduced, and personal protective equipment can be provided for workers to use. This concept is commonly presented as a material moving through layers of cheese containing holes (Swiss Cheese) as illustrated in the figure below.

“The Swiss Cheese Model” illustrates that it is usually necessary to use a combination of measures to appropriately manage to reduce exposure to a hazard.© University of Bergen/Arjun Ahluwalia

Share this

Occupational Health in Developing Countries

Occupational Health in Developing Countries

Reach your personal and professional goals

Unlock access to hundreds of expert online courses and degrees from top universities and educators to gain accredited qualifications and professional CV-building certificates.

Join over 18 million learners to launch, switch or build upon your career, all at your own pace, across a wide range of topic areas.

Register to receive updates

-

Create an account to receive our newsletter, course recommendations and promotions.

Register for free