What is 3D modelling and what is it used for?

Find out what 3D modelling is, what it is used for and how to learn 3D modelling.

3D modelling is used to shape many of the things we see in our everyday lives. From video games to architecture, we’ve all likely benefited from 3D modelling technology.

But what exactly is 3D modelling? What is it used for, and how does it work? Here, we explore the intricacies of 3D modelling and all of the wonderful things it is used for.

What is 3D modelling?

Let’s start with a 3D modelling definition. 3D modelling is the process of creating three-dimensional representations of an object or a surface. 3D models are made within computer-based 3D modelling software, which we’ll explore a little later.

During the 3D modelling process, you can determine an object’s size, shape, and texture. The process works with points, lines, and polygons to create the 3D shapes within the software.

How does 3D modelling work?

A 3D model is essentially made up of vertices, which come together to form a mesh and act as the core of the 3D model. Each point on the model can be manipulated to change the shape. By using coordinate data, the software identifies the location of each vertical and horizontal point, all relative to a reference point.

The most common way to begin making a 3D model is to start with a basic shape – a cube, box, sphere, or whatever you think is best suited. From your starter shape, you can start moulding and refining it into what you desire.

What is 3D modelling used for?

Many industries utilise 3D modelling for a range of projects; there are likely loads of 3D modelled items we use without even realising its involvement. With 3D modelling, the opportunities are endless. It’s a truly versatile medium that can be used for an array of different areas. Let’s explore some common uses of 3D modelling:

Game development

Perhaps the most commonly known use for 3D modelling is game development. 3D models are used to create characters, settings, props, and entire worlds within video games. The key to any good game is immersion, and 3D modelling is a great way to build immersive experiences.

3D modelling is particularly important within the world of virtual reality gaming, which is an extremely exciting sector. Virtual reality games fully immerse you in the game experience, creating entire three-dimensional worlds to dive into.

To learn more about creating immersive games, check out our Create Expressive Videogames course.

3D printing

It makes sense that 3D printing would not be possible without 3D modelling. 3D printing lets 3D models become physical objects which can be used for anything you set your mind to. It’s a lot more than just miniature figures and toys from at-home printers; there are endless useful ways to utilise 3D printing.

As we discovered in our 3D printing in healthcare open step, 3D printing is frequently used within healthcare which has life-changing effects. It has been used to make custom-built prosthetics and implants and to create anatomically correct models for surgical planning.

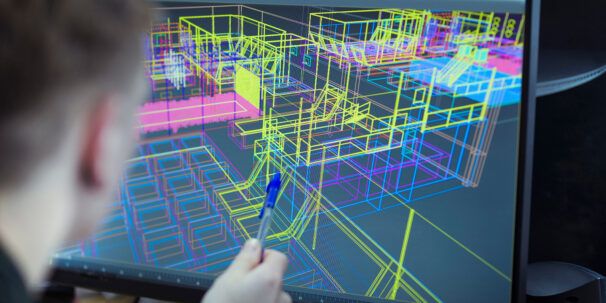

Architecture

Another common use of 3D modelling is architecture. 3D modelling lets architects plan beyond the traditional method of hand-drawn building plans. As technology has evolved, we’re now able to conjure up a three-dimensional visual of a building before it is fully built.

This is extremely useful for envisioning the final product during pitches or to other stakeholders. 3D modelling can reveal potential issues with building structures that 2D plans could not show and is key to modern building design.

Animation

Once you have a 3D model, it can be completely rigged and animated – which comes in very handy for animation. Animators use 3D models for a clean, seamless effect when creating movies and TV shows. Throughout the process, 3D modelling is used to create scenery, characters, props, and much more.

Most animated movies will utilise some kind of 3D programming software. Being able to animate isn’t exclusive to animation, however. It also comes in handy for special effects within movies, amongst other things.

If this branch of the 3D modelling world interests you, check out our Explore Animation course.

Product design

Many of the products we see around us in our day-to-day lives would have had some 3D modelling involvement. By creating a virtual 3D model of your product before it is physically created, we can pinpoint any errors and adjust the product accordingly. Even being able to see the object’s size relative to other products can make a huge difference in the production process.

It is also useful for pitching product ideas to investors, as products can be showcased at a 360-degree angle, allowing stakeholders to fully envision the final result. It’s also less wasteful than creating samples and repeatedly making mock-products, and sustainable product design is a great step in the right direction.

Types of 3D modelling software

With so much potential and variety within 3D modelling, there is an equally wide range of software to match. 3D modelling software comes in different price ranges, are specific to different purposes, and all have unique features. Let’s delve into some examples of 3D modelling software:

Blender

This is an open-source 3D modelling software that is available to download for free. It’s a great place to start your 3D modelling journey, and it can be used for various different mediums.

Some common uses of Blender include visual effects, animation, and 3D printing models, to name just a few. It supports almost every aspect of 3D modelling, so it’s great if you want to work on different projects.

AutoCAD

Another computer-aided design software, AutoCAD is a drafting and design software that can be used for both 2D and 3D projects. It is popular amongst architects and engineers. It is also very handy for product design and helps prevent product failures before production.

Unlike Blender, this 3D modelling software is not available to download for free. It’s worth noting that you can simply download a free trial to get to grips with how the software works.

Autodesk Maya

This software is incredibly powerful and is mostly used for animation (even by leading animation studios). It is even considered the industry standard for animation and is a lot more advanced than Blender.

It is, however, a lot more expensive than most. For that reason, it is probably worth starting your journey with free or cheaper software until you’re an expert. Additionally, it is a lot more difficult than Blender, as there are so many additional features.

Best software for 3D modelling

So, with so many options to choose from, how do we know what the best software for 3D modelling is?

This can be a tricky question to answer, as it will depend entirely on you and your projects. The software comes in different levels of complexity, some are better for certain projects but they all have functions that differ.

If you’re looking for a good 3D modelling software for beginners, we’d recommend Blender. The software is user-friendly, easily accessible, has many uses, and is free to download. Often described as easy to learn, this 3D modelling software is great for those starting with 3D modelling software.

In our Intro to 3D Animation using Blender course, you can explore the basics of the software.

How to learn 3D modelling

By now, you’re probably wondering how to get started with learning 3D modelling. The good news is the resources to do so are readily available. All you need is the motivation to learn and access to the internet!

Plenty of the software needed to teach yourself the basics are free to download, or at least offer free trials, and there are many resources available online that can help you along the way.

3D modelling courses

It’s entirely possible to learn the ways of 3D modelling software at home. Online courses are a great way to start, and often guide you through the entire process until you’re comfortable with the software. It’s an easy way to have someone show you the ropes at any time and place.

We’ve outlined some of our highly-rated courses that will set you up for success within 3D modelling:

- Introduction to 3D modelling

- Intermediate Additive Manufacturing (3D printing)

- Introduction to 3D animation using Blender

- Introduction to Digital Manufacturing and 3D printing

- Introduction to Virtual, Augmented and Mixed Reality

- Construct a Virtual Reality Experience

- How to Make and Sell Your First Immersive Experience

Once you’re comfortable with the fundamentals of 3D modelling, you’ll be able to practice and hone your skills. You’ll be creating games and designing buildings in no time!

How to make your 3D model

What your first 3D project will depend greatly on where you’re learning and what you’re learning. However, it’s always a good idea to start simple. Pick up the basics and become comfortable with the software you’re using. You’ll eventually pick up the pace and be creating fully-fledged 3D models of anything your heart desires.

Since a lot of online courses will walk you through the process of making something, you’ll likely start with their suggestion. You could also play around with the software and see if you can make a personal project once you know the basics.

In our Introduction to 3D modelling course, you’ll learn the basics of 3D modelling and also get the chance to make your very own 3D model project.

Is 3D modelling worth learning?

The answer to this is simple – absolutely! The industry is incredibly fast-paced, with lots of room for creativity and job opportunities. Whether you’re eager to find a new hobby or you’re trying to tap into a fun techy career, 3D modelling is the way to go.

The 3D space is full to the brim with new opportunities. Take the metaverse, for example, a fully three-dimensional environment taking the world by storm. The 3D mapping and modelling market is even projected to grow by 17.2% between 2022-2027.

With the 3D modelling space being relevant in so many industries and increasing in popularity with increased technological advancements, it’s a great area to work in. Some of the roles you could land yourself with 3D modelling skills include, but are not limited to:

Final thoughts

3D modelling is an exciting space with lots of opportunities to learn and be creative. It’s also a fast-growing industry with lots to offer. Hopefully, this article has helped expand your 3D modelling knowledge and set you up with the motivation to master it.

Can’t wait to start creating? Why not sign up for one of the highly-rated courses we outlined above?